Door Manufacturing Software: Why Notebooks and Excel Are Holding Your Business Back

When you start a business alone or with a partner, your accounting system can fit in your pocket. A paper notebook is reliable; it requires no electricity and no training. You write down the measurements, fulfill the order, get paid, and cross out the line. The cycle is complete.

But businesses tend to grow. Hired employees appear: managers, measurers, several installation teams, a production workshop. At this moment, the notebook stops coping, turning into a bottleneck that physically prevents the company from developing further.

Old records get lost, and finding the contact details of a client you installed doors for a year ago becomes an impossible quest. Moreover, if your manager decides to quit, they take the entire client database with them—simply by putting their diary in their bag.

For those planning to evolve rather than just exist, a tool of a different level is required.

The Illusion of Control in Excel

The first logical step to getting an order management program is often Excel or Google Sheets. It is better than paper, but for door manufacturing, it is still a crutch.

A spreadsheet is a flat list. You cannot conveniently attach site photos, drawings, scanned contracts, or call recordings to a cell in a way that is easy to open. You cannot separate access: if you give a link to a measurer to enter data, they see the entire database, including financial indicators they shouldn’t know. If you don’t give access, you have to copy information from messengers manually.

Managing a complex production process in spreadsheets is like drilling concrete with a manual hand brace. It is theoretically possible, and you will make the hole. But professionals use a hammer drill.

If you want to build a system that runs like clockwork, you need a specialized tool. Usually, such programs are called “CRM for manufacturing”, but even for small businesses, this concept is too narrow (as it focuses mostly on clients and sales). Rather, you need a simple ERP system—a single source of truth where everyone works: from the sales manager to the installer on-site.

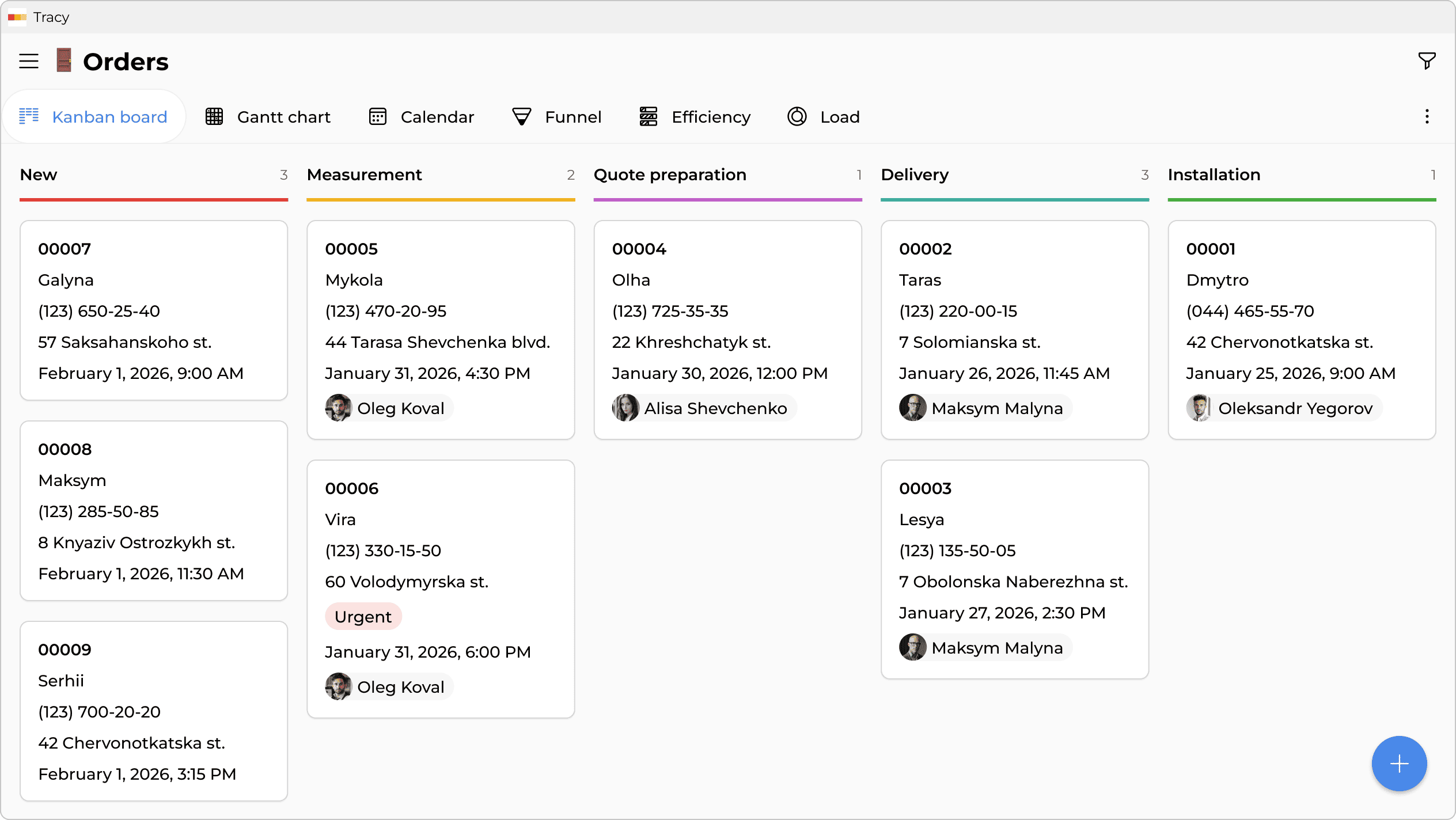

Let’s look at what this looks like in practice by taking an order through all stages.

Stage 1. From Lead to Measurement. The End of “Broken Telephone”

Imagine an ideal process. A client leaves a request on the website or calls. The system is integrated with telephony and web forms, so a client card is created automatically. The manager only clarifies details and agrees on a time for the measurer’s visit.

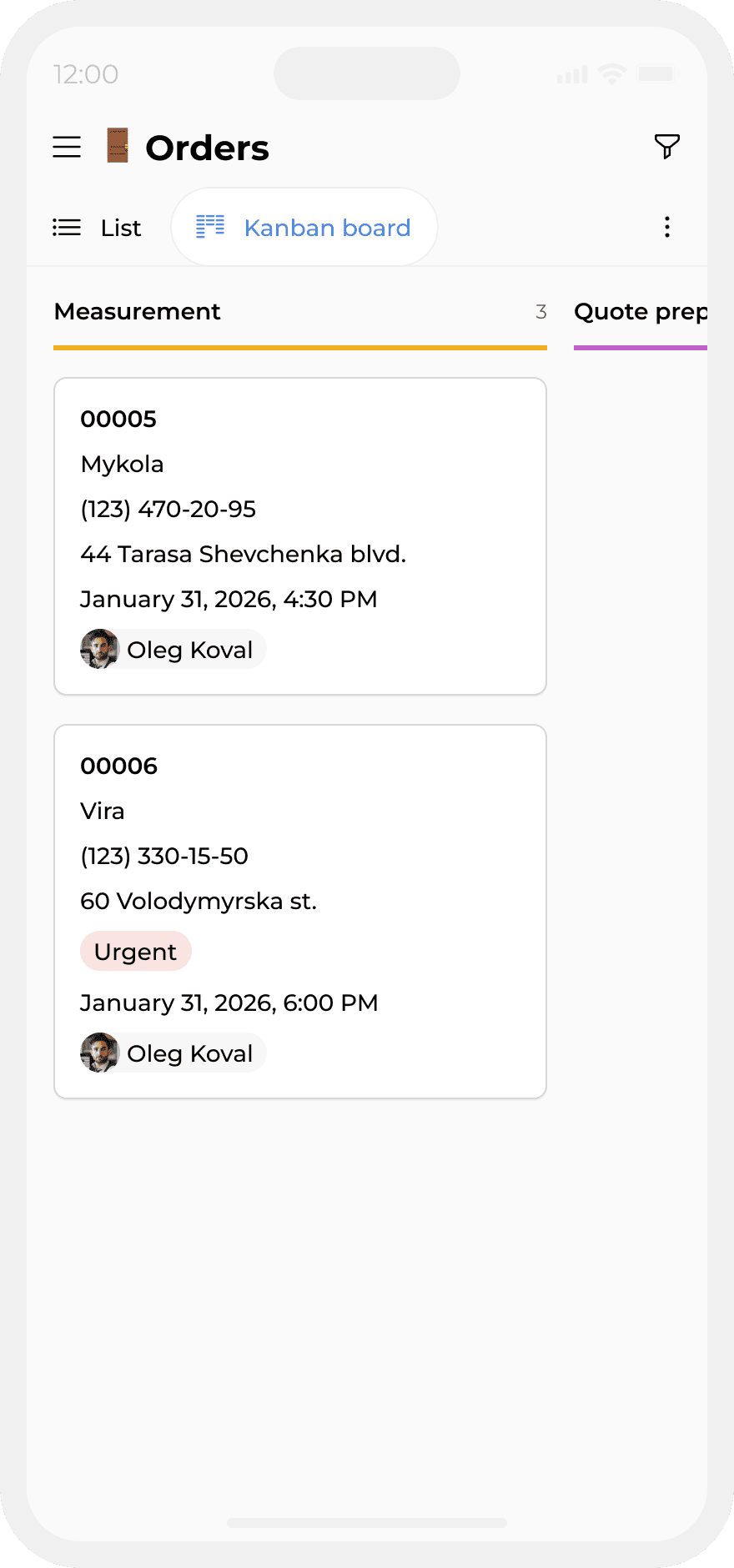

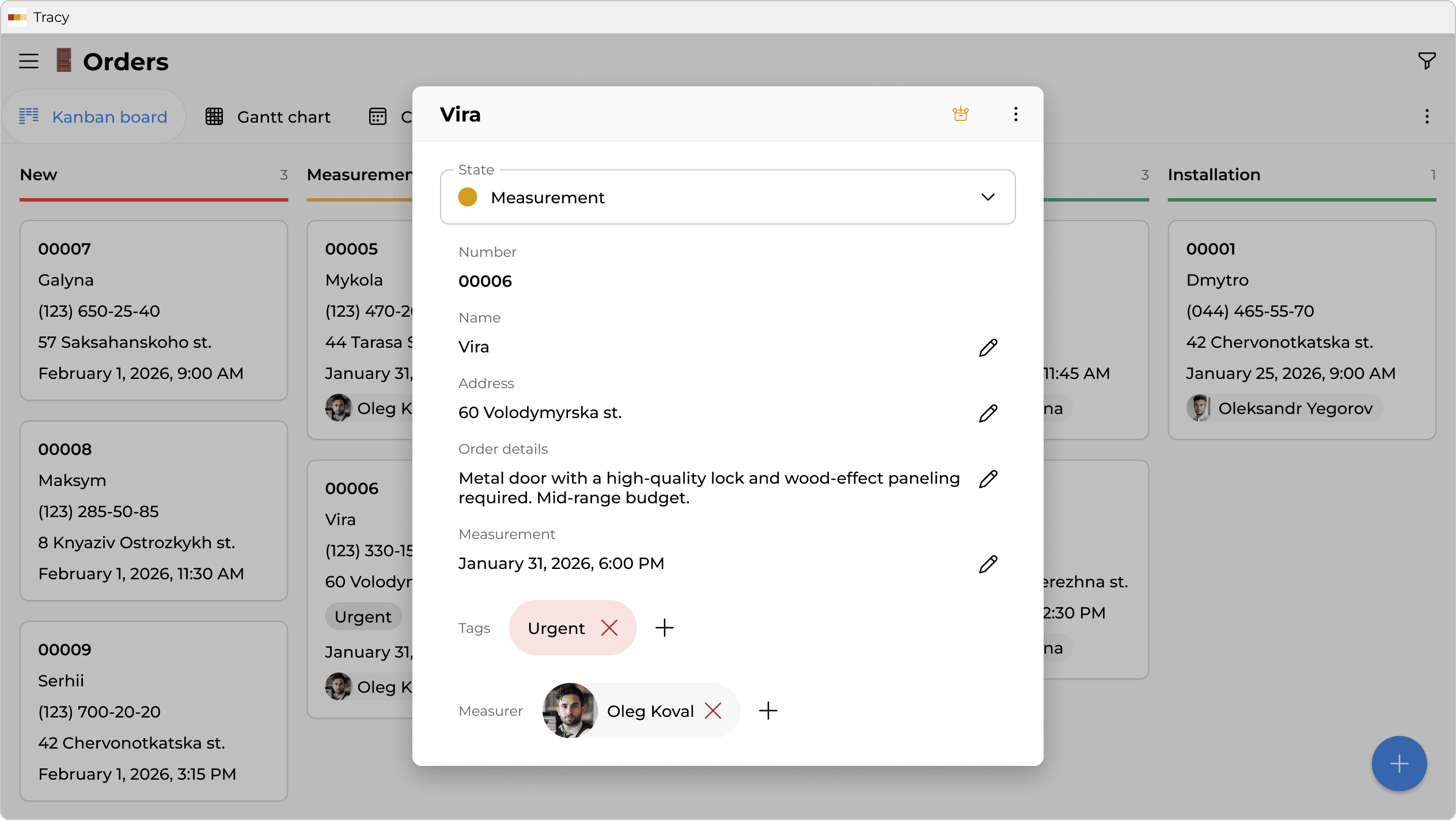

Here begins the magic of role-based access. The measurer receives a notification on their smartphone. They have the same app installed as the director, but with limited functionality. They see only their tasks and only the necessary part of the data: address, time, client name.

They arrive at the site, take measurements, and enter them directly into the order card on their phone. The system can require mandatory uploading of photos of the doorway—without this, the measurer simply cannot close the task.

Result: The manager in the office sees the measurements and photos the very same second. They don't need to wait for the measurer to return to the office or decipher blurry photos in Viber, trying to guess which one belongs to which order.

Stage 2. Quote and Approval

Having precise data, the manager generates a Quote (Commercial Proposal). It is uploaded directly to this specific order.

Next is the critical moment of approval. In the classic scheme, the manager sends an email with an attached file, and the client writes “Ok” or “Approved”. This is a weak link: you can mistake the file version, or send something to production that the client didn't actually approve.

A modern system allows you to generate a “guest link” for the client. The client clicks it and sees their order: specifications, drawings, total sum. They cannot change anything, but they have a “Signature” field. The person literally signs with their finger on the smartphone screen.

This signature is fixed in the system. The order moves to the “Approved” status. No copying, no “that’s not what I meant”. A single digital document for everyone.

Stage 3. Paperless Production

After the prepayment is made (which is also recorded as a separate field), the order enters the production queue.

A large monitor or tablets can be placed at the masters’ workstations in the workshop. They see the order queue: what needs to be done right now, which deadlines are burning. Important: production does not need to see the sale price, client contacts, or chat history. The system automatically filters the data, showing the master only the technical assignment, drawings, and deadlines.

This eliminates chaos. The master doesn’t run to the manager to clarify details, and they don't work with old versions of drawings because the system always has current information.

Stage 4. Installation Like Clockwork

When the doors are ready, the manager changes the status to “Ready for Installation” and assigns a team.

The installer, like the measurer, accesses the system via a smartphone. Up to this moment, their app could be empty (“No orders”). As soon as they are assigned, a Push notification arrives, and a card appears with the address, time, and technical details.

The installer is required to upload “Before” and “After” photos.

Additional Benefits of a Centralized System

Besides simple order tracking, a unified workspace for the team opens up opportunities that Excel users can only dream of:

- Live Portfolio. You don't need to search for examples of work in your phone gallery among personal photos. The system automatically pulls up photos of completed jobs. You can filter in a second: “Show all white classic doors” and show the client real photos from your sites, immediately seeing what hardware was used and how much it cost.

- Handling Complaints. You can create a separate process for defects or rework. This allows you to accumulate statistics: if the same installer constantly goes out to adjust hinges a week after installation, it’s a reason for a serious conversation or training.

- Exact Costing. By implementing time and material tracking at each stage, you will see the real profitability of each order. This allows you to manage discounts flexibly and understand where you are making money and where you are breaking even.

A Tool That Adapts to You

Many entrepreneurs are scared of the word “implementation”. It is associated with months of development, huge budgets, and complex staff training.

Precisely to avoid these problems, we created Tracy.

It is a no-code platform that allows you to create your own business management app without hiring programmers. The main advantage of Tracy is simplicity and flexibility.

You don't get a monster with a thousand unnecessary buttons. You configure the system so that each employee sees only what they need. For an installer, this might be just one button and two fields for photos. This approach significantly reduces team resistance—people don't need to learn complex software; everything is intuitive.

Tracy becomes the central control panel for your company. Here you can manage not only clients and production but also your supplier database, warehouse stock, internal office tasks, or marketing activities.

We have developed a special template for door manufacturers that already takes into account the processes described above. You can take it as a base and easily adapt it to the specifics of your production. This is a fast way to move from chaos in notebooks to a systematic business ready for scaling.

Dmytro Sikorskyi

Dmytro Sikorskyi