5 Problems in the Furniture Business That Can Be Solved With a Management System

You can make high-quality furniture, work with expensive materials, and have a backlog of orders for months ahead, and still lose profit. Why is this happening? Because the ideal process in the furniture business is not just about quality products. It is a complete chain: from finding a customer and agreeing on technical specifications to production, quality control, delivery, installation, and after-sales service.

Instead, 70% of manufacturers still collect data manually, and processes are not streamlined:

- orders are kept in messengers and spreadsheets;

- drawings are stored in notebooks and folders;

- installation is postponed “after the fact” because someone forgot to report a delay;

- managers get lost in presentations because they cannot quickly find examples of work or current prices.

As the number of orders grows, such “trifles” turn into systemic losses: money, time, and customer trust.

In this article, we will look at the five most common problems in the furniture business and show how a modern management system helps to solve each of them.

How do furniture companies manage orders without a centralized system?

Each business scale has its own approaches, but they all have a common problem—information is stored in different places and is not collected into a single picture:

- Small workshops or sole proprietors. They start with the simplest: a notebook, Excel, and correspondence in messengers. This allows them to quickly take orders and control the basic stages. But as soon as the number of customers and projects grows to even 3, this approach stops working: information gets lost, and it becomes difficult for the manager to keep everything in mind.

- Medium-sized companies. Partial use of accounting programs, spreadsheets, and shared folders. On the one hand, this is already better than a paper notebook, but on the other hand, the data is scattered across several tools. Files on the disk are not synchronized with the accounting department, and the manager's agreements are not always consistent with production plans. As a result, the team spends time searching and clarifying instead of working.

- Large manufacturers. Here, separate accounting systems are usually installed: accounting programs, tools for warehouse management, or schedule planning. But they also work separately from each other. For the manager, this means that there is still no complete picture—they have to call different departments and manually collect information about the status of orders.

In all three cases, the result is the same: data is scattered, the business loses control over processes, and this directly affects the bottom line. After all, the greatest risks arise where the business depends on external factors, for example:

- when agreeing on details with a client or designer, there can be dozens of revisions, and without a system, it is easy to get lost in the versions: someone was sent the old version, someone is working with an outdated drawing, and so on;

- Delays in the delivery of materials or fittings automatically push back the deadline for production and installation, and one missed stage triggers a domino effect for the entire order.

Such situations imperceptibly eat away at time and profit: the team works more than necessary, and the business receives less than it could.

What is a furniture production system?

A furniture production system is a digital tool that combines all of a company's processes into a single chain: from finding a customer to warranty service.

Its main goal is to replace spreadsheets, paper folders, and messenger correspondence with a clear and structured platform where:

- all order data is stored;

- managers can see the full history of cooperation with the customer;

- production receives clear specifications and deadlines;

- purchasers control stocks and know what to order;

- installers work according to a precise schedule;

- management has access to up-to-date analytics at any time.

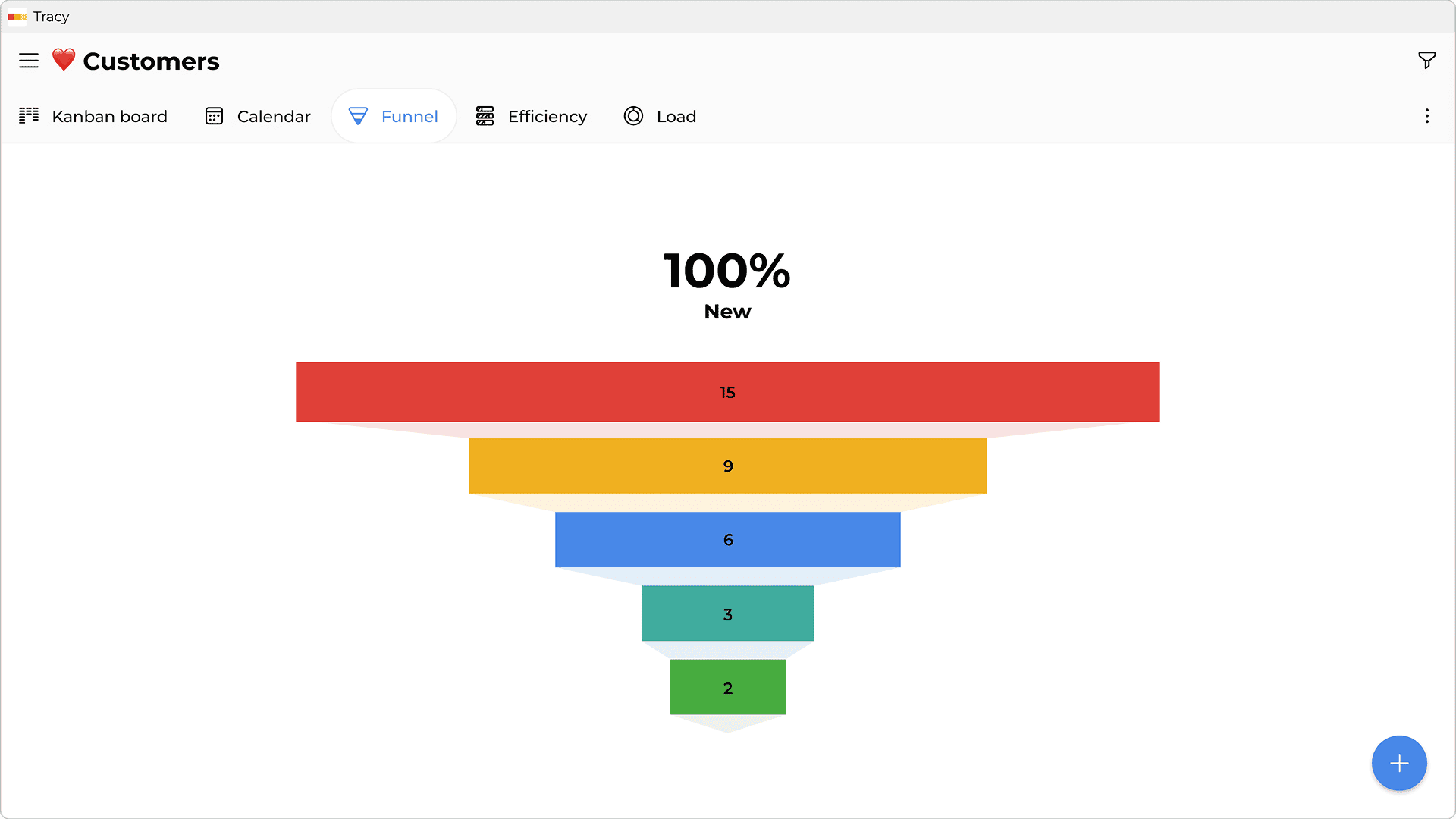

An example of analytics in a furniture production system.

What features can a system for furniture production have?

CRM for the furniture business

The system stores the entire customer base with communication history: calls, correspondence, agreements. Managers receive task reminders, see deal statuses, and can quickly pick up a colleague's work without losing context.

Sales accounting

If one manager goes on vacation, the other will have all the information about the customer and the order: forming orders, invoices, and acts in the system, recording payments, controlling deliveries, and statuses at each stage.

Load planning

Managers can see who is working on a specific project and when. This makes it easier to control deadlines, avoid postponing deliveries to customers, and immediately understand when a new order will be ready.

Order tracking

Each order has a digital card with specifications, drawings, responsible persons, and statuses. This eliminates confusion with document versions and helps to keep track of project history.

Delivery and installation

Routes are formed, deadlines and responsible persons are assigned. Installers leave feedback in the system, so the customer and management can see the current status of the work.

Analytics for management

Reports show workshop loads, costs, schedules, order sources, and profitability. This helps make decisions based on numbers rather than intuition.

Mobile version of the system

All employees can work directly from their smartphone or tablet. This is often lacking in large systems, while in no-code solutions such as Tracy, mobility is a key advantage. It is no coincidence that, according to research by Toxsl, mobile applications have increased communication efficiency in manufacturing sectors by 50%. This proves that digital solutions work not only for the office.

5 problems that prevent the furniture business from working smoothly and making money

1. No quick access to the history of completed projects

For example, you are at a meeting with a client and showing examples of your work. Suddenly, you hear the question, “How much did this kitchen cost?” and realize that you have no answer.

To find the exact figure, you have to make phone calls, dig through old correspondence, or search through archives. The client sees confusion instead of professionalism, and this directly affects the employer's image. This situation erodes trust and reduces the chances of a sale.

How does a system for the furniture business solve this?

The system creates a centralized archive of all projects—specifications, budgets, photos, drawings:

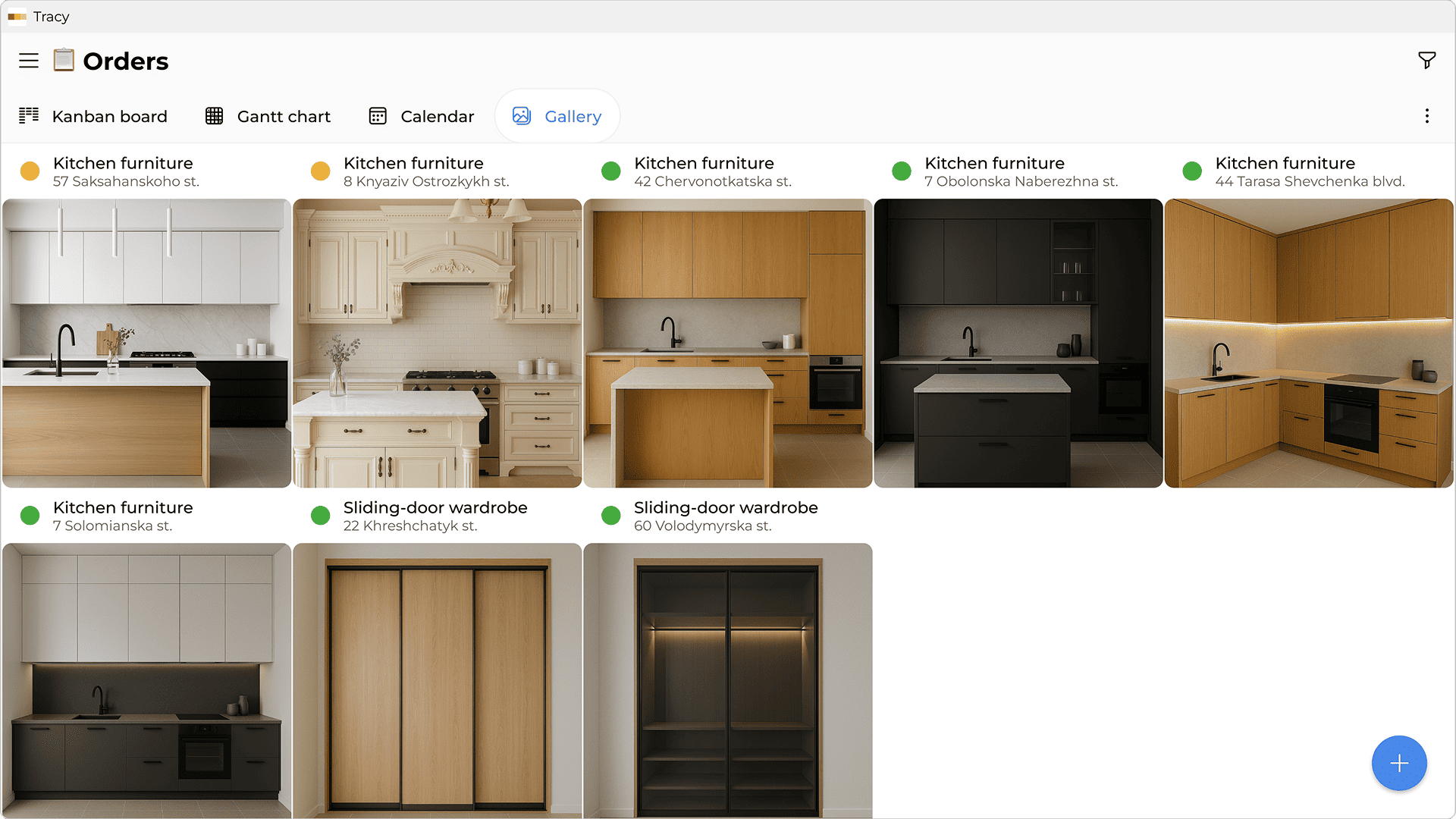

Example of a gallery in the Tracy system.

Need to guide the customer? It only takes a few seconds to find the product and name the price range. The person immediately understands whether the price is right for them, and together you select options for their request on the spot.

2. The entire communication history is in the manager's head

A manager who has been accompanying a customer for several months leaves the company. All agreements, nuances, and even informal promises remain with them. Yes, someone may leave information before leaving. But others simply disappear.

In such a situation, a new employee has to start from scratch: they have to ask the client questions again, clarify details, and check emails and messengers.

For the client, this may seem strange and incomprehensible: what was agreed upon earlier has been lost, and the new manager is not aware of the previous conditions.

How does the system solve this for the furniture business?

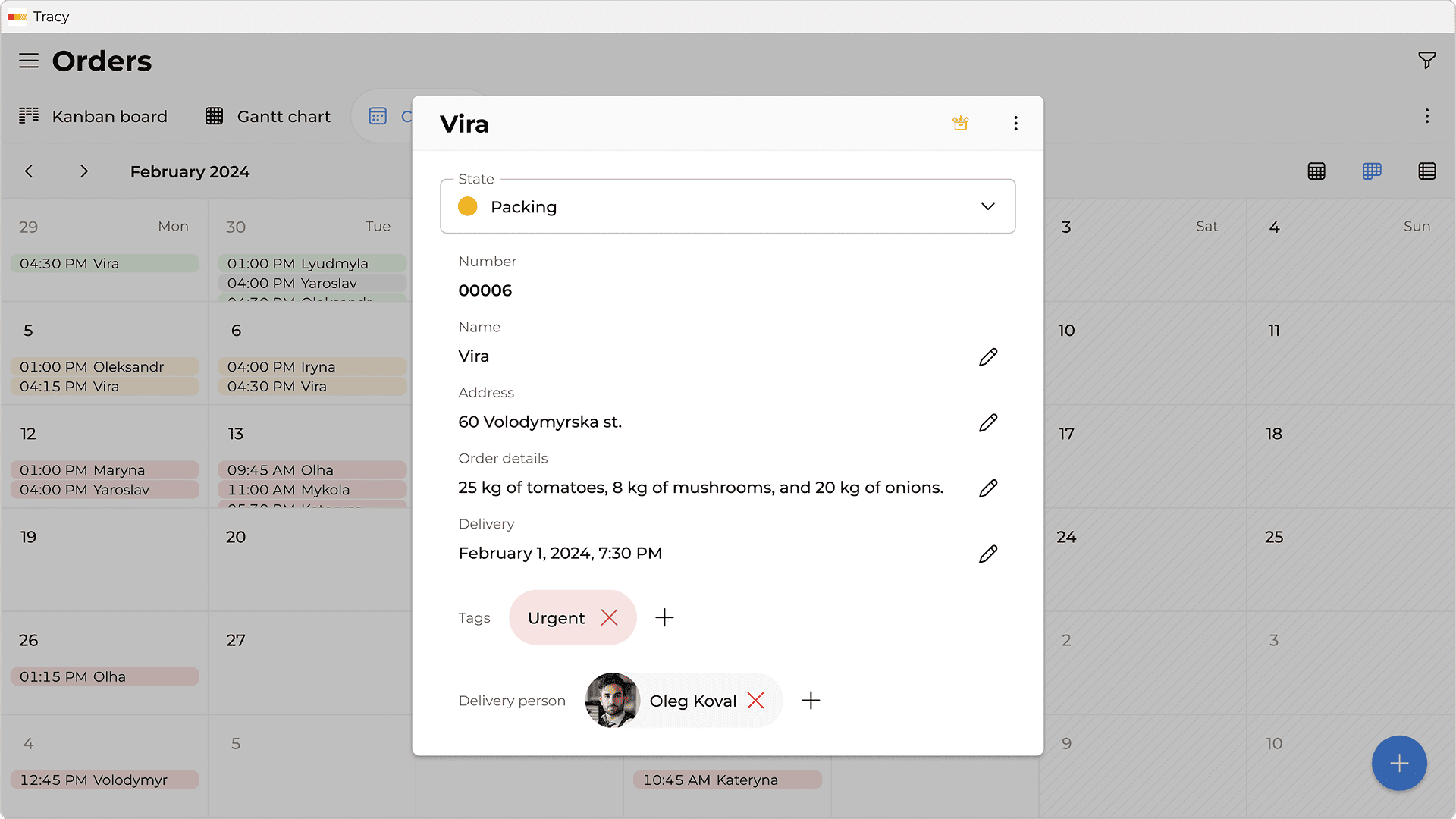

All calls, correspondence, tasks, and statuses are stored in a single customer card. Any manager can open it and immediately see the full history of cooperation: what has already been discussed, what materials have been agreed upon, and what conditions remain open.

When people change, the service remains stable. The customer feels consistency and professionalism, and the company does not waste time and money repeating work that has already been done.

An example of a customer card in a system for furniture production.

3. Order information is not organized

Does the customer want to return to a product you manufactured 5 years ago? You start looking for drawings, specifications, and material data and find that some of the documents are in your email, others are in a folder on a flash drive, and the rest have long been lost. Or the archive simply deleted the data due to a limited storage period.

The repeat order has to be designed from scratch, as if it were a new product.

How does the system for the furniture business solve this?

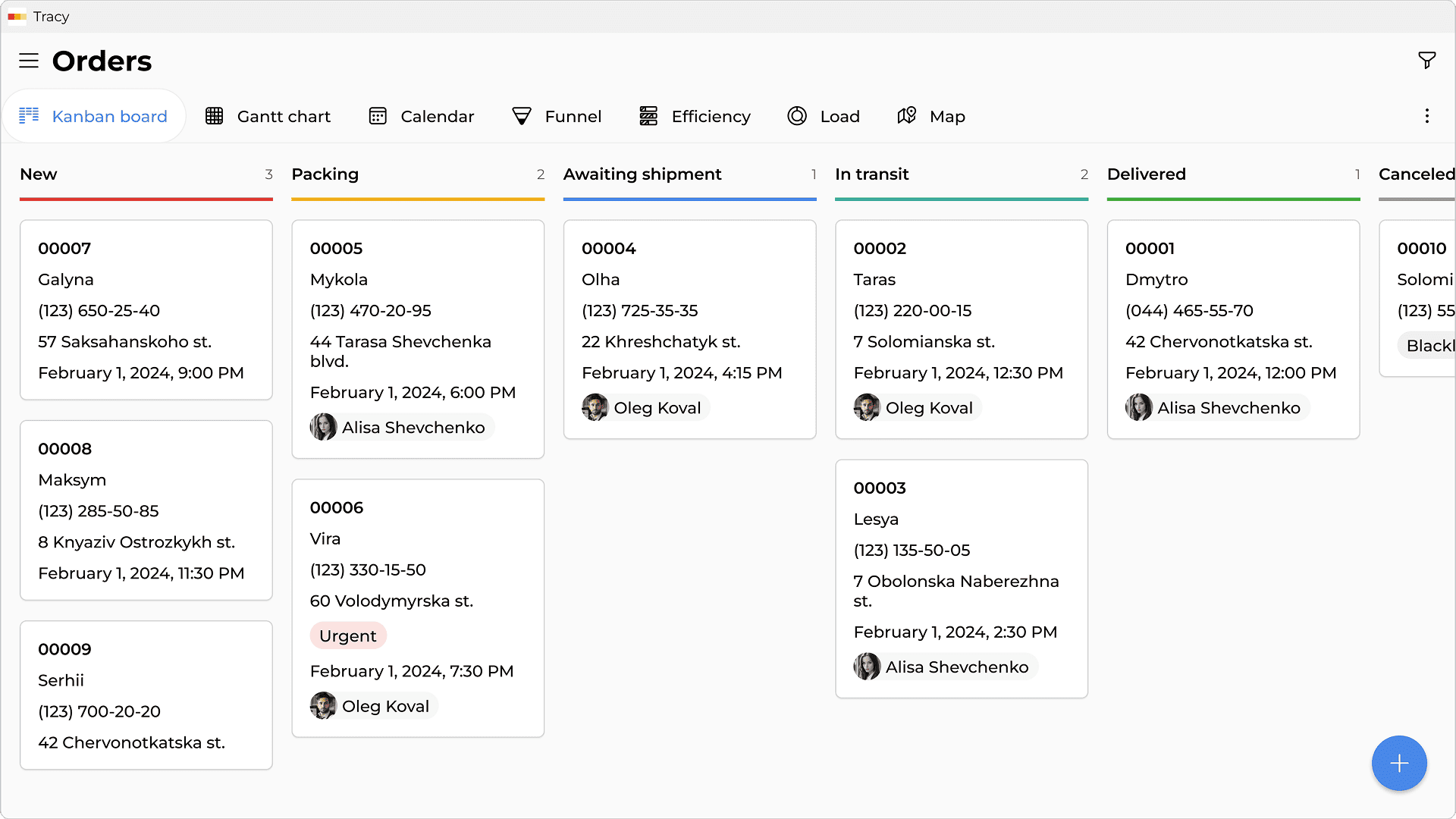

Each order has a digital card where all the data is collected. You can always return to an old project, because the necessary information is available in the system indefinitely until you delete it yourself.

An example of a board with orders in the furniture manufacturing app.

4. Communication between departments is disorganized

Every manager or executive of a furniture company has faced this: to find out what stage an order is at, you have to call the workshop, the buyer, or the warehouse. Often, delays are discovered a few days before shipment, when the customer is waiting for the finished product, and it has not even been completed yet.

The consequences are obvious: deadlines are pushed back, managers spend more time and energy on communication, and customers may have a negative experience. In the worst case, this turns into conflicts that damage the company's reputation.

How can a production management system solve this?

In the system, each stage has its own status and place for feedback. The manager opens the application and immediately sees everything related to the order—there is no need to make dozens of calls. Communication takes place directly within a single screen: everyone leaves comments, attaches files, or flags issues.

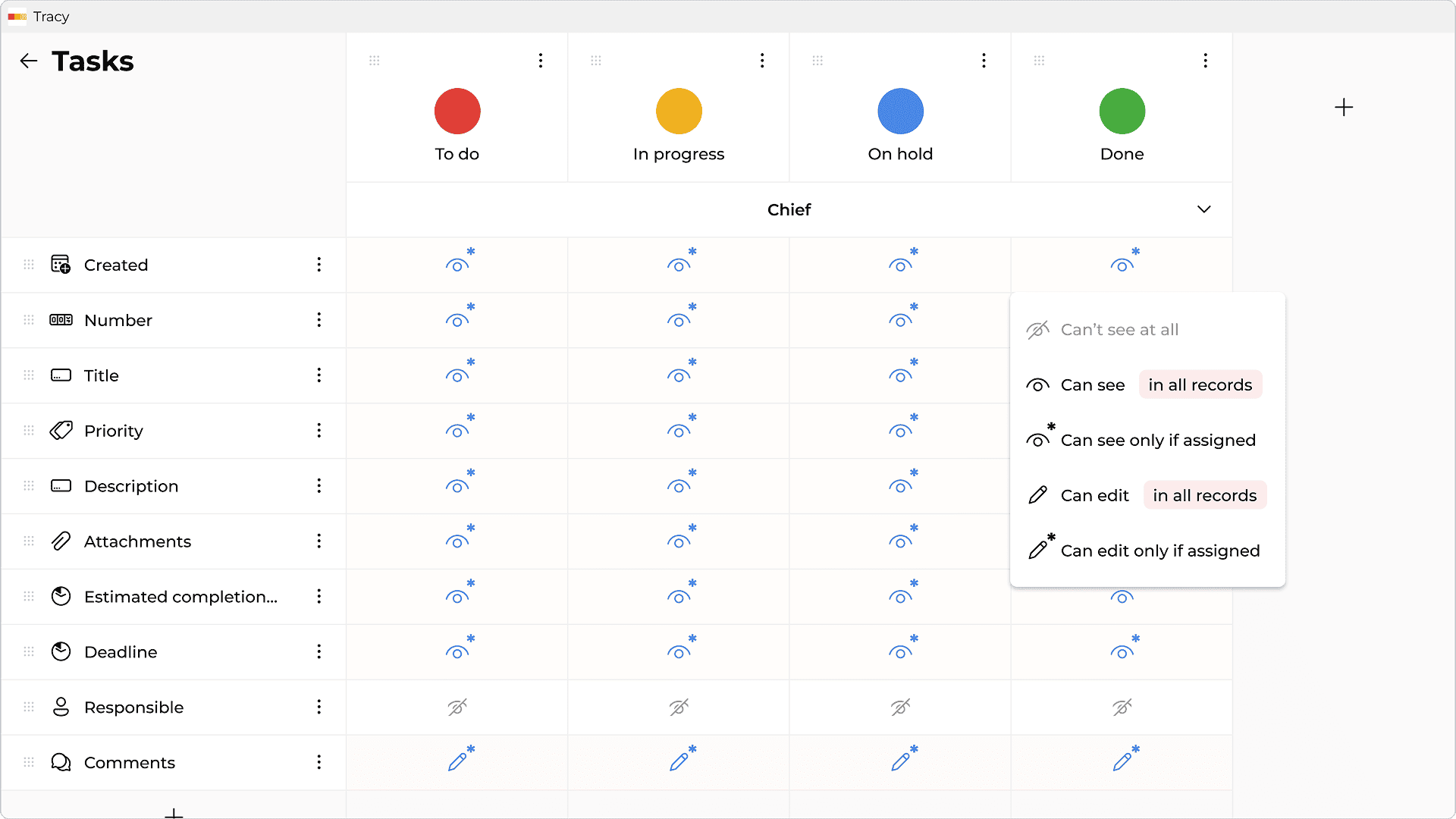

And in Tracy's no-code solution, each employee sees only what is relevant to their role, rather than everything at once. No unnecessary fields—only relevant tasks and clearly distributed access based on roles:

5. Complaints are not recorded or analyzed

Technicians going out for rework, redeliveries, or replacement parts are a standard occurrence in manufacturing. But if every third order ends in a complaint, margins decline.

When such cases are not recorded, the company does not see the true scale of the problem. There is no analysis: is it the oversight of an individual employee or a weak point in the process itself? As a result, money is lost.

How can a system for a furniture company solve this?

All complaints are recorded in detail: what work was redone, how long it took, and how much it cost. The system generates analytics by stage and by person responsible, showing where the failures occur. For example, is the issue at a specific stage of production or in the work of a specific employee?

In this way, the company reduces the number of reworks, makes profits predictable, and understands how to improve the quality of work.

What will the business gain after implementing the program for a furniture company?

- Time and resource savings. The team spends less effort on searching and clarifying, and communication becomes more focused.

- Fewer mistakes. The structure and mandatory steps in the system prevent data loss or skipping important stages.

- Full process control. The status of orders, risks, and bottlenecks are visible at any time.

- Support during implementation. The support service helps to quickly configure the system and train the team to work with it. An important advantage for Ukrainian companies is that all communication is conducted in their native language.

How to calculate the payback period of the system for a furniture store

- Determine the basic costs. Calculate how much the company is currently losing: team time spent on searching and coordination, errors in documents, complaints, repeat visits. This is the starting point for calculations.

- Compare the costs of complaints before and after implementation. For example, after a year of working with the system. The difference will show the amount of money returned.

- Estimate the increase in completed orders by the same team. Thanks to structured processes and automation, you will be able to handle more projects without increasing your staff. This is additional profit that directly affects the return on investment.

The experience of the company POLYWOOD shows that the return on investment of the system can only be assessed some time after implementation. Already in the first season after launch, POLYWOOD saw the difference—the busiest billing day passed without overloading the team, and all shipments were completed on time.

This means that the investment began to pay off immediately, recouping costs by reducing manual labor and increasing order turnover.

Conclusion

Examples from real manufacturers show that implementing a system is a tool that changes the way a business operates as a whole.

Shik-Galichina started as a small atelier, and today it is a factory with a full production cycle and hundreds of representatives throughout Ukraine. But growth also brought new challenges: chaotic accounting, shipping delays, and a lack of management analytics. To overcome these problems, the company implemented a unified system, and now all departments work in sync:

- warehouse accounting is done without Excel;

- shipments are controlled and accelerated;

- management receives reports in real time.

The result: transparent control of each stage, faster logistics, and increased production efficiency without additional costs.

If you recognize your business in the five problems mentioned above, it's time to take a step forward. A management system for a furniture company is an investment that pays off faster than a customer can choose a fabric color :)

FAQ

How does a system for furniture production differ from a task manager?

Conventional task managers (such as Trello or Worksection) are suitable for managing simple projects, but do not take into account the specifics of the furniture business. They do not have ready-made templates that take into account customers, orders, suppliers, production processes, deliveries, and complaints. A system for furniture production (such as Tracy) takes all these aspects into account and allows you to see the whole picture on one screen.

We have a small production facility. Won't the system be too complicated?

It is important to choose the right system. Make a list of tasks that need to be solved and make sure that the program does not have too many unnecessary complex functions in the interface. Usually, systems are designed to scale with the company. You can start with basic features—customer accounting, Kanban boards for tasks, and a calendar. Then, you can gradually add more complex modules. In no-code business systems like Tracy, the interface is intuitive and works like a construction set, so implementation does not require technical training.

What about shop floor workers? Will they be able to work with the system?

Yes. For manufacturing, it is important that workers can quickly find out what to do and when. For example, the Tracy business system has a convenient mobile interface: workers can see tasks, attached files, deadlines, etc., and mark when they complete their stage of work. Fewer calls—more order.

Inna Shapravska

Inna Shapravska